Precision Manufacturing

Enabling Every Lightweight Solution

From mold development to global delivery, we ensure every critical detail for the mass production of complex products.

Precision Manufacturing

Enabling Every Lightweight Solution

From mold development to global delivery, we ensure every critical detail for the mass production of complex products.

Product Applications

Leveraging expertise in precision manufacturing management for professional OEM automotive aluminum alloy components, we extend our applications to meet the lightweight needs of every industry.

of Professional Experience

Patent Technologies

Annual Total Production Capacity

National-Level "Specialized, Refined, Unique, and Innovative" Little Giant Enterprise

IATF

IATF 16949 Certified

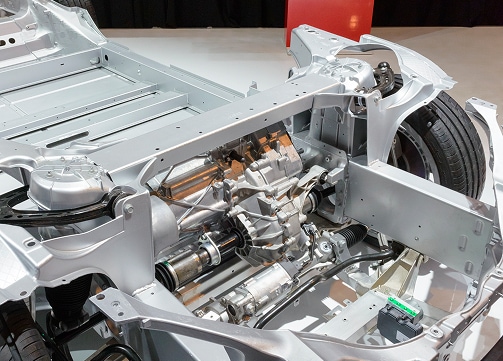

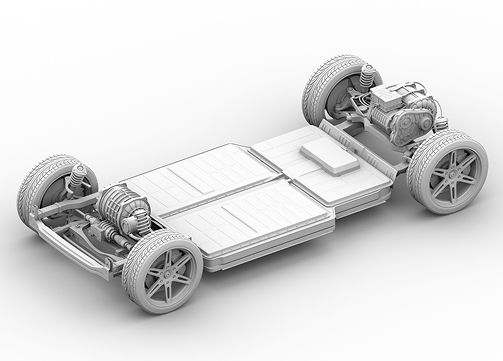

Chassis and Suspension Systems

Aluminum alloy forged components for air suspension, shock absorption, braking systems, control arms, and tie rods are utilized in the chassis structures and braking systems of many renowned vehicle models.

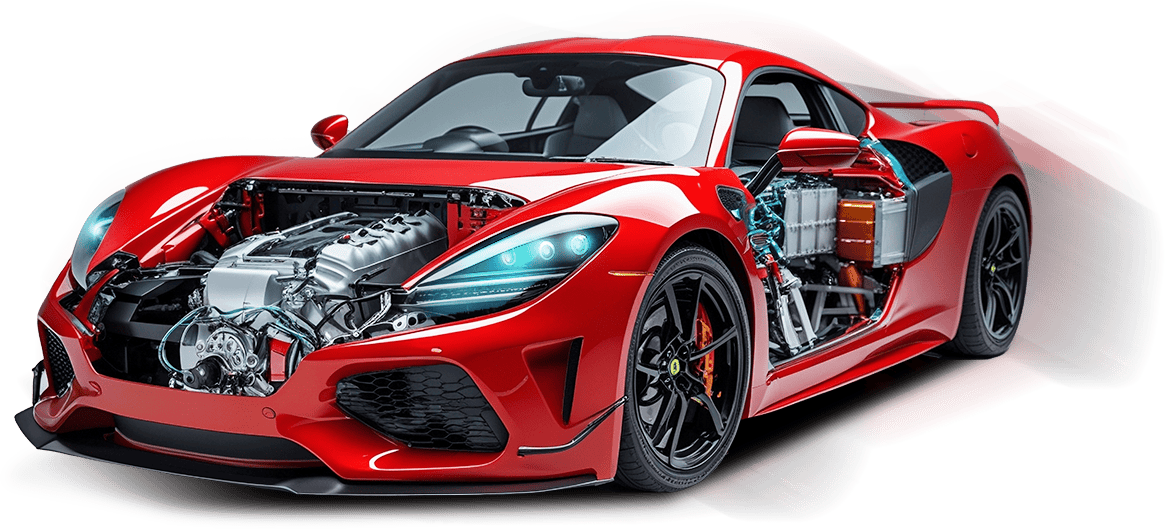

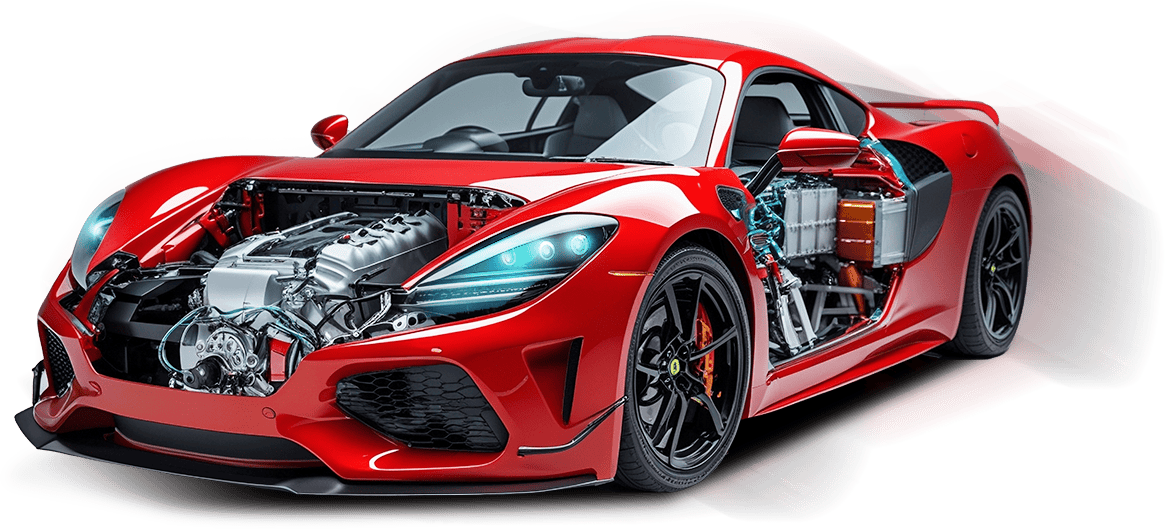

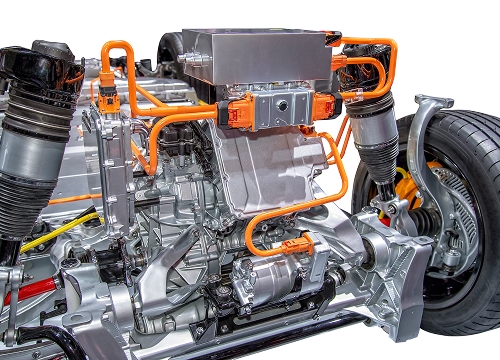

Automotive Powertrain System

Lightweight aluminum alloy forged components are used in new energy electric vehicle motors, engine transmission systems, fuel supply systems, and pulley systems.

Body and Structural Components

Aluminum alloy forged body structural components and forged fasteners combine the advantages of high strength and lightweight properties.

Automotive Electronics & EV Applications

Aluminum alloy forging is used in structural components for battery packs, battery coolant valves, coolant quick connectors, and aluminum materials for charging equipment in new energy electric vehicles.

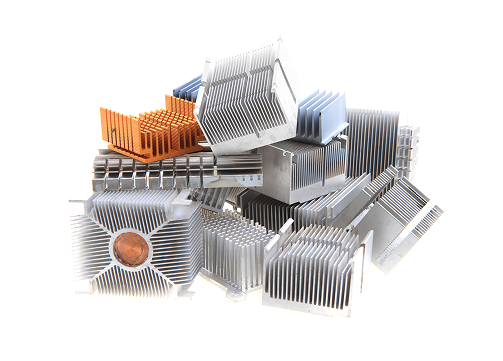

Thermal Management parts

Aluminum forged heatsink and coupling UQD/CDM for Al modules,automotive and electronicdevices cooling systems.

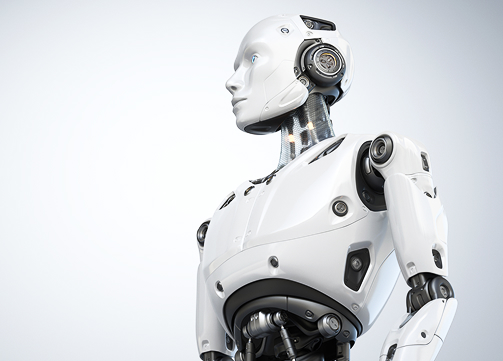

Forward-Looking Application Fields

Humanoid robots, structural components for aerial drones, and structural parts for semiconductor process equipment, meeting the lightweight needs across industries.

Integrated Precision Manufacturing to Build Your Competitive Edge

Specializing in high-precision manufacturing of complex aluminum alloy components, we ensure comprehensive improvement in efficiency and quality from design validation to mass production delivery.

One-Stop Manufacturing Platform for Rapid Response to Demands

With in-house mold, fixture, and jig development teams, we meet customer design and validation requirements. Full-process autonomous control of manufacturing techniques, combined with project-based management, ensures optimal cycle times, stable quality, and full traceability throughout.

Multi-Process Integration to Overcome Complex Manufacturing Challenges

By combining cold forging, hot forging, multi-axis die forging, stamping, extrusion, and spinning forming processes, complemented by high-precision forging and CNC composite machining, we cater to customized demands for high-strength, special-shaped, and complex structures.

Serving Multiple Industries with Flexible Adaptation to Diverse Scenarios

Product applications span automotive chassis, electronic heat dissipation, body structures, industrial hardware, and sports equipment. Core components include air suspension systems, pistons, shock absorbers, heat sinks, and camera housings, supporting both low-volume high-mix and high-volume standardized production.

ASIC — Your Strategic Manufacturing Partner

We don't just deliver products; we turn your concepts into reality.

Quality and Process Monitoring

ASIC ensures high consistency and stability at every stage through rigorous process control.

– SPC in-line statistical control

– 100% FQC inspection on key dimensions

– ISO / IATF certified quality system

– Precision inspection equipment and full traceability

The Preferred Choice of World-Class Brands

For 30 years, ASIC has become a long-term partner to multiple global brands by delivering consistent quality, flexible production capacity, and reliable delivery efficiency. We believe that data reflects proven capability and forms the foundation of customer trust.

Responding to Your Every Need with Technology and Experience

From aluminum alloys to composite materials, we assist clients in achieving process solutions that balance lightweight design with high precision.

Alloy Seiko Industry Co., Ltd.

No.39 Long-gang North Rd., Pingxi Community, Pingdi Town, Longgang Distict, Shenzhen City,Guangdong, China

Alloy Seiko Technology Co. Ltd.

No. 99 Xingjiang Road, Jiangyan District, Taizhou, Jiangsu